Aluminum PCB – FN07

Description

Product Specification:

| Layer: | Single layer |

| Profile: | CNC+V-cut |

| Copper Thickness: | 1OZ |

| Board Thickness: | 1.6mm |

| Surface Finished: | HASL lead free |

| Base Material: | Aluminum Core laminate |

| Break Down Voltage for Insulated Layer: | >2kV |

| Thermal Conductivity for Insulated Layer: | 1.0W/m-K |

What is a Metal Core PCB (MCPCB)?

A Metal Core Printed Circuit Board (MCPCB), also known as a thermal PCB or metal backed PCB, is a type of PCB that has a metal material as its base for the heat spreader portion of the board. The thick metal (almost always aluminum or copper) is covering 1 side of the PCB. Metal core can be in reference to the metal, being either in the middle somewhere or on the back of the board. The purpose of the core of an MCPCB is to redirect heat away from critical board components and to less crucial areas such as the metal heatsink backing or metallic.

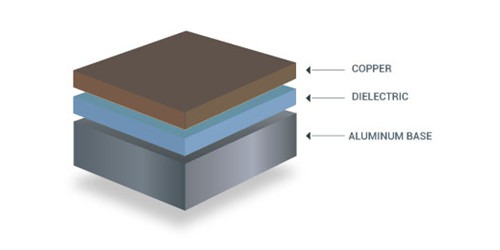

| SINGLE LAYER MCPCB |  | It consists of a single copper conductive layer on top, a metal base plate (e.g. Aluminum) to provide rigidness to the circuit board and a thermal conductive dielectric working as the insulator. |

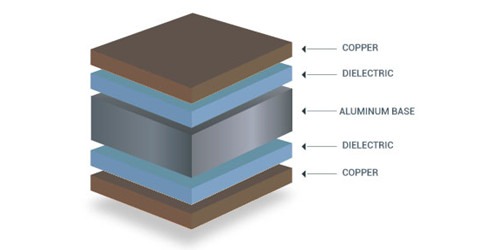

| DOUBLE SIDED MCPCB |  | It has two copper layers and the metal core is between the copper layers. Plated Through Holes (PTH) are used to interconnect the acopper layers so SMT and THT components can be placed on both sides. |

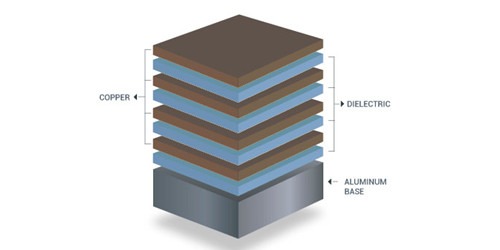

| MULTI LAYER MCPCB |  | It has more than two conductive layers separated by thermal dielectric. In the bottom of the structure is the metal base. SMT components can only be placed on one side. Not THT components are allowed, but it provides the possibility to make blind and buried vias with internal signal layers and power/ground planes. |